How AI reduces costs and complexity in technical purchasing

The digital transformation does not stop at technical purchasing. But while other areas of business have long been benefiting from automation, networking and data analysis, many purchasing departments in the manufacturing industry still work with methods and tools from the pre-digital era. The result: knowledge silos, manual search processes and a lack of transparency. However, technical purchasing in particular offers enormous potential for efficiency gains, cost reductions and greater transparency. Digital, AI-powered solutions open up new possibilities here.

Technical buyers are under increasing pressure from unstable supply chains, volatile prices, and global crises. At the same time, components must be manufactured to fit precisely, procured at short notice and purchased at market prices. Standardization as a relief? In practice, this is usually not the case. Outdated systems mean that drawings are sent by email, quotes are compared manually and supplier information is managed in Excel lists or in the minds of experienced colleagues. Added to this is time-consuming data maintenance, especially when ERP systems access incomplete or outdated information. Decisions are often based on gut feelings and experience, not on data.

This is particularly problematic for components that require drawings. Not only is there a lack of clarity regarding prices and delivery times, but there is also no intelligent mechanism for selecting suppliers. This leads to higher costs and leaves potential savings untapped. However, those who understand their data and use it in a structured way can make purchasing not only more efficient, but also more strategic. Digital, AI-powered solutions help analyze design data and use it specifically for procurement. They enable faster and more accurate classification of components, informed supplier selection and the identification of potential savings. In this way, purchasing becomes a lever for efficiency and strategic growth.

AI makes technical data usable for purchasing

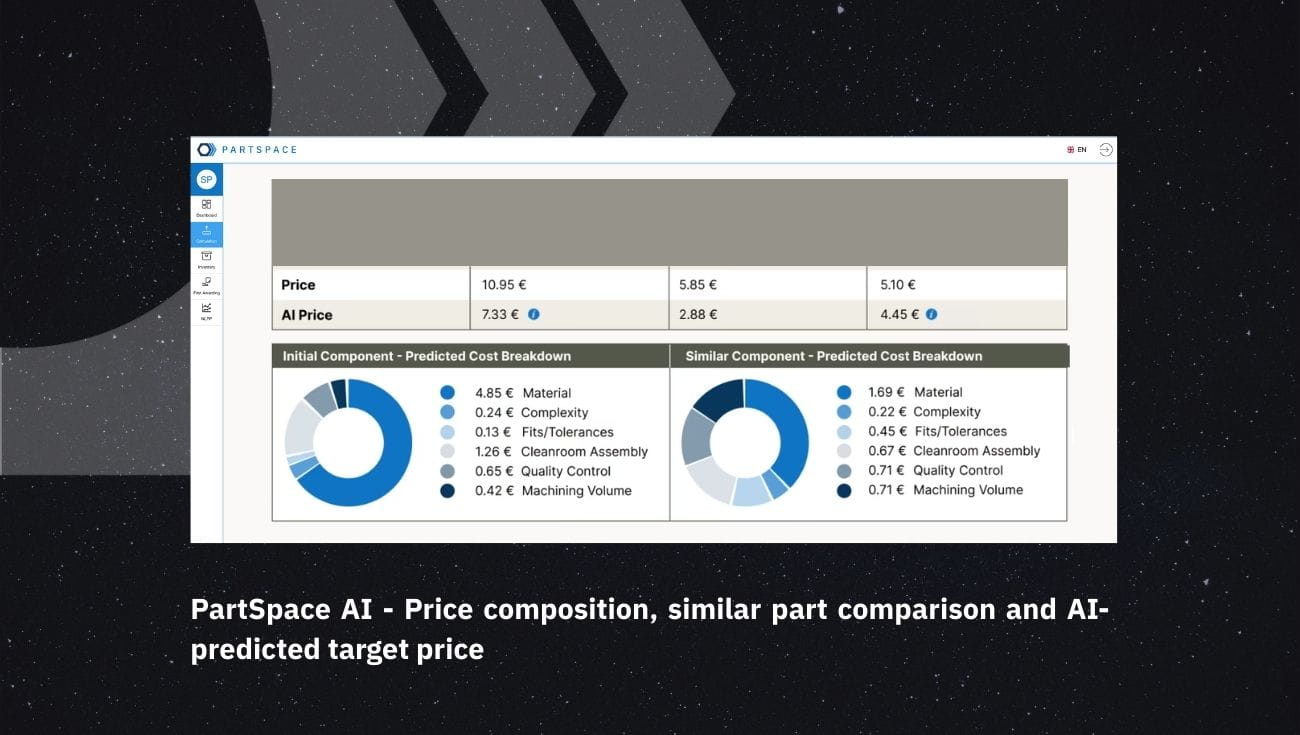

Artificial intelligence comes into its own where data has previously remained unused. It helps to make information accessible and automate processes, but also supports strategic decisions in a well-founded manner. Its greatest strength lies in recognizing patterns in complex technical data. AI can be used to avoid manual errors and time-consuming assignments in parts classification. Components are assigned directly to the correct material groups, technical characteristics are analyzed and suitable suppliers are suggested from an existing network. The efficiency gains are particularly noticeable in the quotation process: instead of manually comparing different formats, AI analyzes incoming quotations in a structured and objective manner, based on defined parameters such as price, delivery time, material or manufacturing method. The result: direct comparison, transparent decisions and significant time savings. AI also plays a key role in pricing. Similarity analyses and the linking of design data with actual purchase prices result in well-founded target price proposals that provide a solid basis for negotiation.

An often underestimated factor in the purchasing process is implicit knowledge about suppliers, such as their response speed, queries or quality. This information often remains invisible but can be automatically captured by AI systems and converted into evaluation patterns. AI also speeds up the search for suppliers. Instead of manually searching through directories, the system compares technical drawings with known manufacturing capabilities and suggests suitable suppliers, objectively and transparently.

PartSpace AI: the first AI that understands technical drawings

One example of the use of such technologies is the intelligent software PartSpace AI. This cloud-based solution analyzes CAD drawings, recognizes manufacturing features and links them to historical purchasing data and external market information. The AI model used was developed specifically for technical purchasing. Unlike traditional systems, which mostly rely on text or ERP data, the AI model was specifically trained to recognize relevant features in CAD drawings and 3D models, from dimensions and tolerances to materials and post-processing methods. The AI automatically analyzes, structures and links this information with historical purchasing data and external market information. The structured data generated in this way forms the basis for a wide range of applications: from strategic purchasing, cost engineering and supplier benchmarking to standardization and quality assurance.

“Our AI is a digital assistant that not only understands what a component is, but also how it is manufactured, which production processes are most suitable and what target price seems realistic. It is precisely this depth that makes the difference in technical procurement,” explains Robert Hilmer, CEO and co-founder of PartSpace. “Technical data is not only processed automatically, but also strategically evaluated and made usable. This ensures particularly robust analyses and reliable results.” PartSpace AI calculates realistic target prices, identifies potential suppliers and detects duplicate components through similarity analyses. Each company receives an individual, dedicated AI model in a secure cloud environment that is based exclusively on the company's own data. This ensures that sensitive information remains protected but is still fully usable.

While many companies are still experimenting with AI, PartSpace AI is already in productive use, market-proven, and delivering measurable results. “PartSpace AI not only makes technical purchasing smarter, safer, and more future-proof, but also enables savings of more than 10 percent,” says Hilmer.

Click here for more info about Partspace AI features

Conclusion: Those who “understand“ design data procure smarter

The introduction of artificial intelligence in technical purchasing has the potential to transform the entire industry. Smarter purchasing decisions enable companies to reduce costs and realize significant savings potential. Purchasing thus becomes a strategic lever for growth and competitiveness in the manufacturing industry.

By using AI such as PartSpace AI, companies can save time, make processes more efficient, and at the same time gain unprecedented transparency in their purchasing activities. In particular, the intelligent analysis of design data and automated supplier selection offer enormous advantages and enable more precise decisions and faster responses to market changes. For industry, this means that AI is a decisive factor for long-term competitiveness in the global market. Companies that rely on AI improve their internal processes and position themselves as pioneers in digital transformation. At a time when innovation and efficiency are crucial, AI solutions such as PartSpace AI are becoming an indispensable competitive advantage in technical purchasing.